Hawking is a good technology in the pre-stress the application of (3)

Currently the industry produces compressive stress in the process there are several methods, such as shot blasting, rolling, etc., shot compressive stress due to its small performance impact on the workpiece is not, at present only in some less demanding use of the workpiece . Objective that can have a greater rolling compressive stress, in some easy to wear shaft, ball workpiece applications, but too much pressure rolling, simply use the metal work hardening characteristics prone to micro-cracks , peeling and other defects, more importantly, it greatly reduces plastic material, enormous damage on the processing equipment, so the actual use of great limitations.

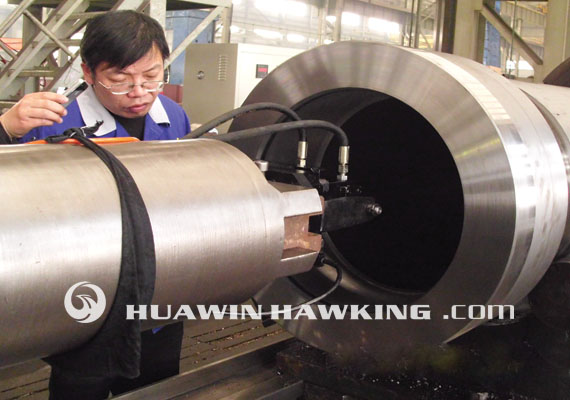

As the machinery industry, cutting-edge processing technology Haoke enhanced metal mirror finish (referred to as USM) technology, good enough to avoid the above process, the metal surface processing, enhanced surface pre-stress achieved good results ever . Its principle is to use metal at room temperature under cold plastic characteristics, the use of Hawk can no abrasive metal parts grinding surface, strengthen and small deformation processing, the surface of metal parts to achieve better surface roughness; the same time In parts of the surface compressive stress, improve part surface hardness, wear resistance and fatigue strength and fatigue life.

Hawk is the only energy technology can improve the surface hardness, good pre-residual stress, not reduce the cold technology of plastic materials.

We are in the same material (40Cr) form two identical parts, a grinding, a Haoke surface finish, surface roughness has been considerable in the case of the two parts to the surface residual stress measurements.

High values of residual compressive stress can significantly improve the fatigue performance of mechanical parts and wear resistance. Respectively 40Cr USM processing and polishing the surface of the specimen after treatment residual stress testing. Test equipment for the STRESS X3000 X-ray diffraction residual stress, the device itself using sinψ prepared to carry the results of residual stress analysis software.

Right in the test results show that: the workpiece by the polished surface of the specimen also had a certain value compression stress, but a smaller value of about 100 MPa, and the thickness is relatively small; and USM machining formed on the metal surface residual stress high compressive stress of up to 700-1000 MPa, the thickness was significantly increased a lot, which is why Haoke technology can greatly improve the fatigue strength of the workpiece causes the workpiece to obtain the mechanical properties greatly improved.

|